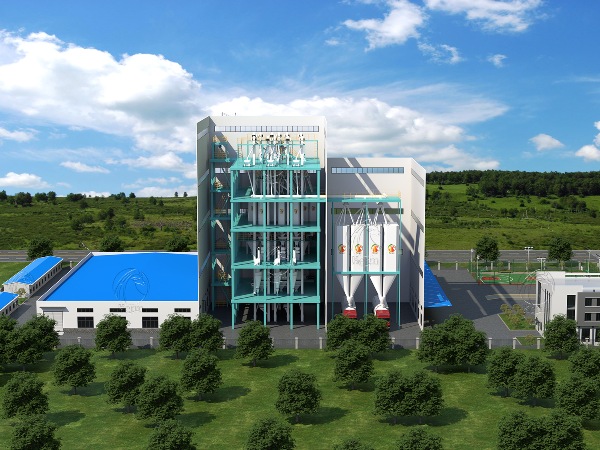

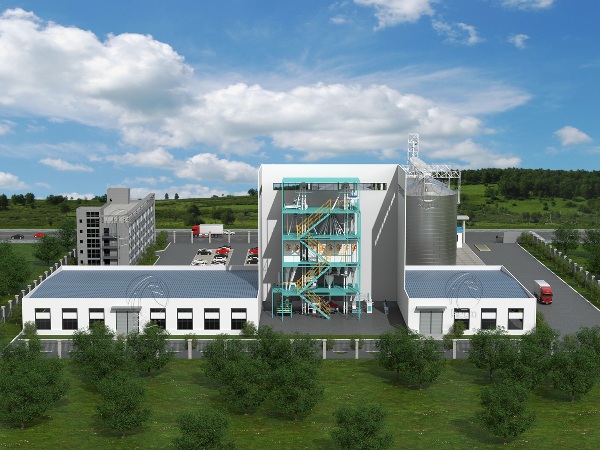

4-5t/h Biomass Wood Pellet Production Line Introduction

Herm machinery large capacity and stable performance 4-5 tons/hour biomass wood pellet production line is specially designed for all manufacturers based on the principle of biomass recycling, such as biomass fuel manufacturers, wood board factories, organic fertilizer factories, feed factories, carton factories The main technological process of the 4-5t/h biomass wood pellet production line: raw material crushing, drying, granulation, cooling, screening, packaging. The main equipment of a complete 4-5 t/h biomass wood pellet machine equipment includes a wood chipper, wood hammer pulverizer, drum rotary dryer, wood pellet machine, countercurrent cooler, vibrating screen classifier, automatic bagging system, electric control cabinet, etc.

Make a Quick Inquiry Now !

Raw Materials Of Biomass Wood Pellet Production Line

Household waste: kitchen waste, vegetable roots, stems and leaves, etc.

Sludge: Sludge that can be granulated mainly comes from wastewater from paper mills, slaughterhouses, livestock, rubber, landfill leachate, dairy products, breweries, and textiles.

Industrial waste: distiller's grains, vinegar residue, cassava residue, sugar residue, silica fume, furfural residue, etc.

Animal manure: a mixture of poultry manure and animal manure, such as manure from slaughterhouses, fish markets, urine, and manure from cows, pigs, sheep, chickens, ducks, geese, goats, etc.

Forestry residues: timber, logs, chips, twigs, leaves, roots, bark, sawdust, bamboo, bamboo chips, sawdust, milling, other forest residues, and waste wood.

Plants: grasses, hay, alfalfa, alfalfa, elephant grass, miscanthus, hemp, hops, etc.

Agricultural waste: cotton stalks, cotton husks, corn stalks, bean stalks, wheat stalks, sunflower holders, sunflower husks, rice husks, bagasse, olive pomace, peanut shells, peanut seedlings, rice bran, etc.

Make a Quick Inquiry Now !

How To Make Biomass Wood Pellet?

1. Woody biomass pellets can be made from sawdust, shavings, wood chips or logs, any forestry waste biomass straw, straw, etc.

2. The pulverizer is used to pulverize larger materials into smaller powders to support the production of wood pellets. The wood shredder is the ideal equipment for shredding raw materials such as wood below 200mm in diameter; if the diameter of the material is less than 50mm, then the wood hammer shredder is the best choice. The optimum thickness of a wood chip is less than 5mm. The particle size of the finished product after crushing can reach 3-5mm in diameter, which is convenient for further processing, drying, and granulation.

3. The optimum moisture content for granulation is about 11-17%. Therefore, before granulation, a dryer is needed to make the moisture content reach the required standard.

4. The pellet mill is an important part of the wood pellet production line, with reliable and stable performance. Capacities range from 1T to 10T per hour. You can choose a ring die pellet mill or flat die pellet mill according to your capacity requirements.

5. After the granulation process, the temperature of the woody biomass pellets is between 60-80 degrees, and the moisture content is close to 15%. So coolers must be used to reduce their surface temperature.

Biomass Pellets Application

- As Biomass Fuel

Biomass pellets are commonly burned as fuel in pellet boilers, pellet stoves, and other pellet appliances in homes. Large biomass particles are usually co-fired with traditional fuels such as coal and oil in large boilers or power plants or factories.

- As Animal Bedding

In addition to being used as fuel and animal feed, biomass pellets can also be used as animal bedding, such as horse bedding, cat litter, etc. Biomass pellets are very popular as animal bedding because biomass pellets are natural products without additives and are highly hygienic, they are the best products for animal bedding.

- As Animal Feed

Biomass straw grass pellets can be a good pellet feed for animals. Compared with biomass, biomass pellet feed has the advantages of cleanliness, balanced nutrition, easy storage, and longer shelf life.