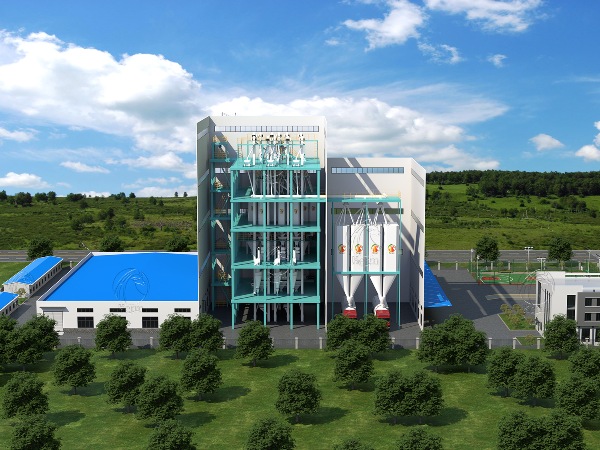

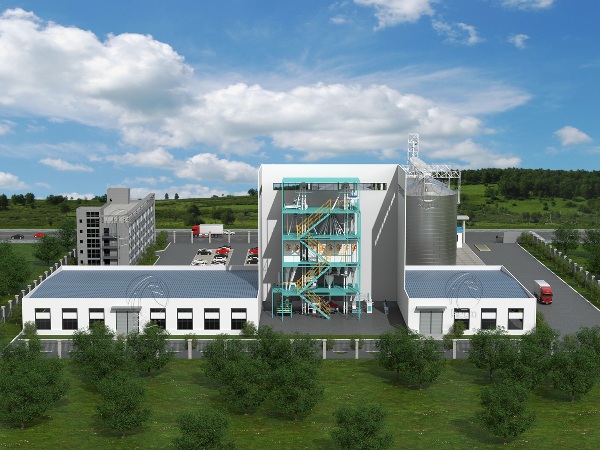

8-10T/H Biomass Wood Pellet Production Line Introduction

Herm Machinery's large-scale fully automatic 8-10 t/h biomass wood pellet production line is specially designed for all production enterprises based on the principle of biomass recycling, such as biomass fuel production enterprises, wood board factories, organic fertilizer factories, feed factories, carton factories, etc. The main technological process of 8-10 tons/hour biomass wood pellet production line: raw material crushing, drying, granulating, cooling, screening, and packaging. The main equipment of a complete 8-10 t/h biomass wood pellet machine equipment includes a wood chipper, wood hammer pulverizer, drum rotary dryer, wood pellet machine, countercurrent cooler, vibrating screen classifier, automatic bagging system, electric control cabinet, etc.

Make a Quick Inquiry Now !

Raw Materials Of Biomass Wood Pellet Production Line

8-10 tons/hour biomass wood pellet production line is mainly suitable for agricultural and forestry waste, hops, wheat straw, wood, sawdust, straw, rice husk, organic fertilizer, chicken manure, cow manure, pig manure, horse manure, wood chips, wood shavings, logs, branches, peanut shells, cotton stalks, corn stalks, olive pomace, coffee shells, coffee grounds, palm trees, oil palm leaves, palm fibers, palm kernel shells, waste paper, hay, alfalfa, bagasse, hemp, etc.

How To Make Biomass Wood Pellet?

- The Crushing Of Raw Materials

The raw material before processing is relatively long or relatively large. If the raw material is broken, the length of the straw should be controlled at about 5cm, so as to avoid too much raw material entering the biomass pellet machine and causing machine blockage.

- The Drying Of Raw Materials

Due to the relatively large amount of water recovery in raw materials. If the user of a large biomass pellet machine can dry the raw material, small processing needs to be air-dried, and the moisture content of the raw material is generally controlled between 15% and 25%. Excessive moisture can easily block the ring die of the biomass pellet machine.

-Raw Material Compression Pelletization

After the raw material is dried, the moisture is moderate, and the pellet fuel can be formed without adding any additives when pressed by a wood pellet machine. It can produce smooth and shiny pellet fuel.

-Cooling Of Biomass Wood Pellet Fuel

The temperature of the produced biomass wood pellet fuel is relatively high, and it needs to be cooled by a cooler before packaging. If the temperature is too high, the packaging is prone to water droplets to loosen the particles. This is not good for sales.

-The Packaging Of Biomass Wood Pellet Fuel

Biomass wood pellet fuel can be packaged with a quantitative packaging machine. It can be packed into 5kg, 10kg, 25kg, etc., which is convenient for small users. It can also be made into a large bag, which is convenient for large users to use and load.

Make a Quick Inquiry Now !

Biomass Pellets Application

- As Biomass Fuel

Biomass pellets are commonly burned as fuel in pellet boilers, pellet stoves, and other pellet appliances in homes. Large biomass particles are usually co-fired with traditional fuels such as coal and oil in large boilers' power plants or factories.

- As Animal Feed

Biomass straw grass pellets can be a good pellet feed for animals. Compared with biomass, biomass pellet feed has the advantages of cleanliness, balanced nutrition, easy storage, and longer shelf life.

- As Animal Bedding

In addition to being used as fuel and animal feed, biomass pellets can also be used as animal bedding, such as horse bedding, cat litter, etc. Biomass pellets are very popular as animal bedding because biomass pellets are natural products without additives and are highly hygienic, they are the best products for animal bedding.