How to Start a Sheep & Goat Feed Production Line in Ethiopia: Complete Turnkey Solutions from Henan Herm Machinery

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With the rise of commercial farming and the need for reliable, nutritious feed for livestock, setting up a feed manufacturing facility for sheep and goats is an excellent investment. Henan Herm Machinery is at the forefront of this industry, offering not only state-of-the-art feed production machines but also comprehensive turnkey solutions. From machine supply to factory design, installation, and after-sales support, we are your partner for success in Ethiopia.

Key Products for Sheep & Goat Feed Production

At Henan Herm Machinery, we provide a wide range of advanced feed-making machines designed to meet the specific needs of sheep and goat farming. Our products are engineered for efficiency, durability, and consistent high-quality output:

1. Feed Pellet Machine

Feed pellets are one of the most effective ways to provide livestock with balanced, easy-to-digest nutrition. Our feed pellet machines are designed to produce pellets that meet the nutritional needs of sheep and goats. The machines feature:

High-Quality Pelletization: The powerful compression of ingredients ensures that each pellet maintains uniform size and density, enhancing feed consumption and reducing waste.

Customizable Die Sizes: Our pellet mills allow you to choose die sizes depending on the specific requirements of your livestock, whether you need fine pellets for younger animals or larger pellets for adult sheep and goats.

2. Hammer Mill

The hammer mill is an essential part of the feed production line, used for grinding raw materials into fine powder. For optimal sheep and goat feed, our hammer mills ensure:

Efficient Grinding: With high-speed hammers, they can easily process grains like corn, wheat, and soybeans, ensuring uniform particle sizes and improved digestibility.

Versatile Processing: Our mills can handle a variety of raw materials, making them adaptable to different feed formulations.

3. Feed Mixer

Uniform mixing of ingredients is key to ensuring balanced nutrition for livestock. Henan Herm’s feed mixers offer:

High Precision Mixing: Our mixers are designed to blend dry and wet ingredients evenly, creating a consistent feed mix that ensures every pellet is nutritionally complete.

Multiple Capacities: We offer various capacities to match your production scale, from small to large volumes, giving you the flexibility to scale up as your business grows.

4. Cooling System (Cooler)

After the pellets are formed, they need to be cooled to prevent them from cracking or degrading. Our feed pellet coolers ensure:

Effective Cooling: The cooler uses airflow to lower the temperature of the pellets and reduce moisture content, ensuring they remain firm and stable.

Improved Storage: By reducing moisture, the cooling process helps to extend the shelf life of the pellets, making them easier to store without spoilage.

Comprehensive Turnkey Solutions

Henan Herm Machinery goes beyond just providing high-quality machines; we offer complete turnkey solutions for setting up your sheep and goat feed production line. Our approach includes everything you need for a successful operation, from planning and design to construction and installation.

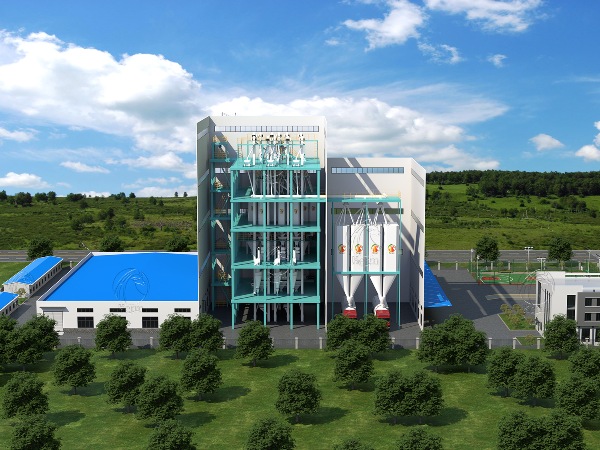

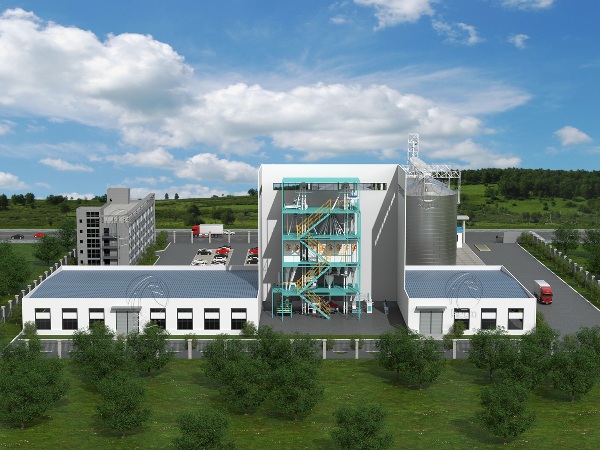

Factory Design and 3D Layout

Before you even start building your facility, we provide detailed 3D design and factory layout planning services. Our professional engineers will work with you to create an optimized factory layout, ensuring efficient production flow and the best use of available space. With 3D visualization, you can see exactly how your feed plant will look once completed, giving you confidence in the design before any construction begins.

Customizable Factory Build

We also specialize in designing and constructing feed factories tailored to your specific requirements. Our services include:

Factory Buildings: We can design and construct modern, cost-effective factory buildings that accommodate your production line and storage needs.

Steel Silos: To ensure proper storage of raw materials and finished products, we provide steel silos that can handle large quantities of feed ingredients and pellets.

On-Site Construction Management: We handle the full scope of the project, from construction planning to execution, ensuring that your facility is built to last.

Installation and Commissioning

Our commitment to your success doesn’t stop with the delivery of machines. Henan Herm Machinery provides installation and commissioning services, where our professional engineers will be on-site to:

Install Machinery: Ensure that all equipment is correctly set up and optimized for efficient operation.

Train Your Team: Provide comprehensive training on how to operate and maintain the machinery, ensuring your staff is fully capable of running the plant smoothly.

Test the System: Run tests to ensure all systems are functioning correctly and that your feed production process is running at peak efficiency.

After-Sales Support

We offer full after-sales support, ensuring that you have access to assistance whenever you need it. Our team is always available for:

Maintenance and Repairs: Quick response times for any issues that arise, ensuring minimal downtime.

Upgrades and Spare Parts: Access to genuine spare parts and optional machine upgrades to keep your production line modern and efficient.

Successful Projects in Ethiopia

Henan Herm Machinery has already established a strong presence in Ethiopia, completing several successful feed manufacturing projects across the country. Our ability to understand the local market, coupled with our experience in designing efficient production lines, makes us the go-to partner for feed production in Ethiopia. We have worked with local farmers and businesses to set up sustainable, profitable operations, helping them meet the growing demand for high-quality animal feed.

Why Choose Henan Herm Machinery?

Expertise and Experience: With years of experience in the feed machinery industry, we know exactly what it takes to build and run a successful sheep and goat feed production business.

Customization: Every farm has unique needs. Our solutions are fully customizable to meet your specific requirements.

Turnkey Solutions: From factory design to machinery installation, we provide a complete package that eliminates the need for multiple vendors.

Local Support in Ethiopia: We have local engineers and a strong after-sales network in Ethiopia, ensuring that you receive prompt and reliable service.

Conclusion: Your Path to Successful Feed Production.

Starting a sheep and goat feed production business in Ethiopia is an excellent investment, and Henan Herm Machinery is here to help you every step of the way. With our advanced machines, customized solutions, and turnkey project services, you can launch your feed production line with confidence. Let us help you create a modern, efficient feed production facility that ensures the health and productivity of your livestock.

Contact Henan Herm Machinery today to get started on your sheep and goat feed production journey in Ethiopia.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Phone/Whatsapp: 0086-18037508651