How to Start a Livestock Feed Factory in Ethiopia: A Comprehensive Guide for Success

As one of Africa's largest agricultural economies, Ethiopia presents a significant opportunity for businesses looking to enter the livestock feed production industry. With a growing population and increasing demand for meat, dairy, and eggs, the livestock sector in Ethiopia is thriving, creating a booming market for high-quality, sustainable livestock feed. If you're considering starting a livestock feed factory in Ethiopia, this article provides a comprehensive guide on navigating the process, including insights on equipment, production, and our successful installation projects in the country.

Understanding the Market Potential for Livestock Feed in Ethiopia

Ethiopia has the largest livestock population in Africa, with millions of cattle, sheep, goats, and poultry. The demand for high-quality livestock feed is rising in line with the expansion of the livestock industry, which is essential for increasing productivity in meat, milk, and egg production.

The key factors driving the demand for livestock feed include:

Rapid Growth in the Livestock Sector: As the agricultural sector modernizes, there is a growing need for specialized feeds that enhance growth rates, milk production, and egg yield.

Increasing Investment in Commercial Farming: Many large-scale commercial farms in Ethiopia are shifting to more efficient, industrialized production methods, driving the demand for reliable, high-quality animal feed.

Government Support for Agriculture: The Ethiopian government is making efforts to boost the agricultural sector, including initiatives to support the livestock industry, making it an opportune time to invest in feed production.

Location and Site Selection for the Factory

Choosing the right location for your livestock feed factory is crucial. The ideal site should be near both the raw material sources and the target market. Here are key factors to consider:

Proximity to Raw Material Sources: Major ingredients for livestock feed, such as maize, wheat bran, and soybeans, are grown in Ethiopia's agricultural regions. Setting up your factory near these farming areas will reduce transportation costs and ensure a steady supply of raw materials.

Access to Transport and Markets: The factory should be located close to transport hubs and key livestock farming areas to facilitate the distribution of feed to farms and reduce logistic costs.

Compliance with Local Regulations: Ensure that your factory complies with Ethiopian industrial regulations, environmental standards, and zoning laws to avoid any legal complications during the construction and operation phases.

Factory Construction and Equipment Setup

Once you’ve chosen a location, the next step is to build the factory and set up the necessary equipment. A livestock feed factory typically includes areas for raw material storage, feed mixing, pelletizing, drying, and packaging.

Essential Equipment for Feed Production: Below are some key machines used in the feed production process that are essential for establishing a successful livestock feed factory:

Hammer Mill (Crusher):

The hammer mill is used to crush and grind raw materials into smaller particles, making them suitable for further processing. It's commonly used to reduce the size of grain, soybeans, and other raw ingredients. The hammer mill ensures a consistent particle size, which is essential for proper mixing and pelletizing.

Feed Mixer:

The feed mixer is an essential machine that blends different feed ingredients into a homogeneous mixture. It ensures that all ingredients, including proteins, grains, vitamins, and minerals, are evenly distributed throughout the feed. There are two main types of mixers used in feed production:

Horizontal Feed Mixers: These provide uniform mixing for bulk materials and are efficient for large-scale feed production.

Vertical Feed Mixers: Ideal for smaller batches, they can mix both dry and moist ingredients effectively.

Feed Pellet Mill:

Pellet mills are at the core of the feed manufacturing process. They compress the mixed feed ingredients into pellets, which are more compact and easier for livestock to digest compared to loose feed. Pellet mills come in different sizes, and the type of die used (flat die or ring die) will depend on the specific needs of your livestock feed.

Ring Die Pellet Mills: These are more efficient for high-capacity production and are typically used in large feed mills, as they produce high-density pellets with a smooth texture.

Flat Die Pellet Mills: More suitable for small to medium-scale operations, flat die pellet mills are simple and cost-effective, ideal for farms or smaller factories.

Feed Shifter:

It is a piece of equipment commonly used in animal feed production processes to shift or move feed ingredients or finished feed from one point to another within the factory. It helps improve the efficiency of feed processing by automating the movement of materials, reducing labor costs, and minimizing the risk of contamination.

Feed Cooler:

The feed cooler follows the dryer to reduce the temperature of the feed pellets, ensuring they don’t lose nutrients. A well-designed cooler also prevents pellets from becoming too brittle during the cooling process, which is crucial for maintaining their integrity during storage and transportation.

Feed Packaging Machine:

The final step in the feed production process is packaging. The packaging machine automatically fills and seals bags of finished feed for distribution. Automated packaging systems improve efficiency, reduce labor costs, and ensure that each package contains the correct amount of feed.

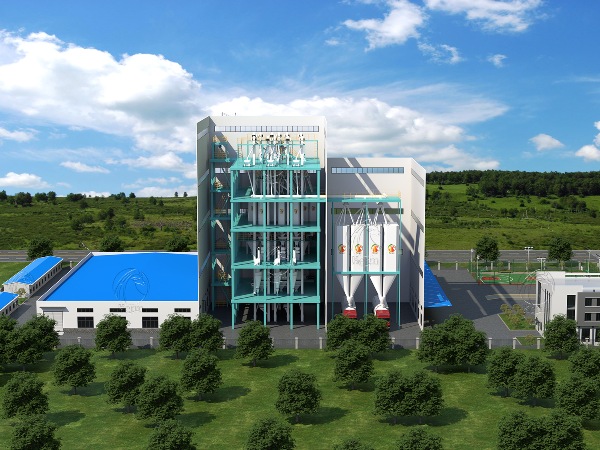

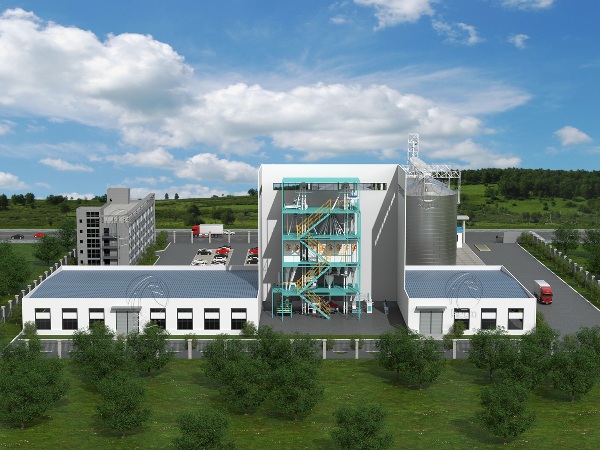

Successful Installation by Henan Herm Machinery Co., Ltd. in Ethiopia: Henan Herm Machinery Co., Ltd. has already successfully installed several complete livestock feed production lines in Ethiopia. For instance, a large feed mill we installed in the Oromia region is running smoothly, providing high-quality feed for cattle, poultry, and goats. The factory was equipped with advanced machinery, including automatic mixing systems, high-efficiency pellet mills, and state-of-the-art packaging equipment.

The installation process was seamless, thanks to our local engineering team, who handled everything from factory layout planning to equipment installation and staff training. This project helped the client significantly increase production capacity and improve feed quality, demonstrating the potential benefits of investing in modern feed manufacturing technology.

Feed Formulation and Product Development

A crucial aspect of starting a livestock feed factory is developing feed formulations that meet the nutritional needs of different types of livestock. The feed formulation process involves:

Understanding Animal Nutritional Needs: Different animals, such as poultry, cattle, and pigs, have unique nutritional requirements at different stages of growth. Developing the right formulation is key to ensuring animals grow healthily and efficiently.

Sourcing High-Quality Ingredients: The quality of your feed depends on the quality of the raw materials you use. It’s important to source high-grade maize, soybeans, wheat bran, and other feed ingredients from reliable suppliers.

Formulation Optimization: Using advanced software and expert knowledge, you can create formulations that maximize feed efficiency and minimize waste. This is where precision in formulation can make a significant difference in the quality of your final product.

For example, feed for dairy cows might be rich in protein and minerals to improve milk yield, while feed for poultry might focus on vitamins and amino acids to enhance egg production. Offering specialized feeds will help differentiate your product in the market.

Staffing, Training, and Operations

Operating a feed factory requires skilled labor, including machine operators, maintenance staff, quality control experts, and production managers. To ensure smooth operations, you’ll need to:

Recruit Skilled Employees: Hire technicians, engineers, and machine operators who are experienced in the feed production process.

Provide Training: Proper training is crucial for ensuring workers can operate machinery safely and efficiently. It also helps maintain high-quality production standards.

Establish Safety Protocols: Safety should be a priority in all factory operations. Ensuring that workers are familiar with safety procedures will reduce the risk of accidents and improve overall efficiency.

At Henan Herm Machinery Co., Ltd., we offer comprehensive training programs for our clients, ensuring that factory personnel are fully equipped to operate the equipment and maintain the feed mill to the highest standards.

Marketing and Distribution Strategies

To successfully market your livestock feed products, you’ll need to:

Build Relationships with Local Farmers: Establishing direct relationships with large-scale farms, cooperatives, and local farmers is key to ensuring demand for your products.

Participate in Industry Events: Engage with the local agricultural community by participating in agricultural expos, seminars, and other industry events to showcase your products.

Online Marketing and E-Commerce: Utilize digital marketing strategies, including social media, website promotion, and online stores, to expand your reach beyond local markets and attract international clients.

After-Sales Support and Maintenance

An often overlooked but critical component of running a successful feed factory is after-sales support. Ensuring that customers are satisfied with the performance of your products and services will help build long-term relationships and improve brand loyalty.

Regular Maintenance and Service: Offer maintenance contracts for your clients to ensure their machinery runs smoothly over time.

Technical Support: Provide ongoing technical support to address any issues with the equipment or production process.

At Henan Herm Machinery Co., Ltd., we provide a dedicated after-sales service team that offers timely support, maintenance, and troubleshooting for all our installed feed mills, ensuring clients’ operations run efficiently.

Conclusion

Starting a livestock feed factory in Ethiopia offers great potential, given the country's robust livestock sector and growing demand for high-quality feed. By investing in advanced machinery, creating specialized feed formulations, and leveraging strong marketing and distribution strategies, you can build a successful feed production business.

With years of experience in designing, supplying, and installing complete feed production lines in Ethiopia, Henan Herm Machinery Co., Ltd. will be your reliable partner, helping you successfully enter Ethiopia and other African markets and promote local agricultural development.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Phone/Whatsapp: 0086-18037508651