Empowering Your Feed Production: Comprehensive Solutions from Herm Machinery

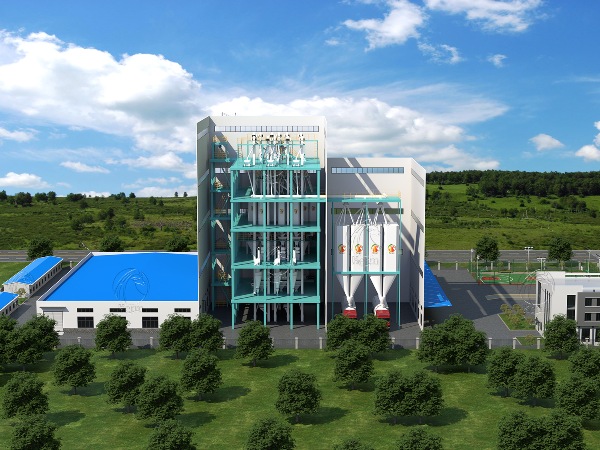

Herm Machinery: Your Partner in Feed Processing Solutions

At Herm Machinery, we specialize in manufacturing high-quality feed granulator machines. Whether you are looking to establish a feed processing factory or need to produce poultry feed for your farm, we have the expertise and equipment to assist you.

Comprehensive Feed Pellet Solutions

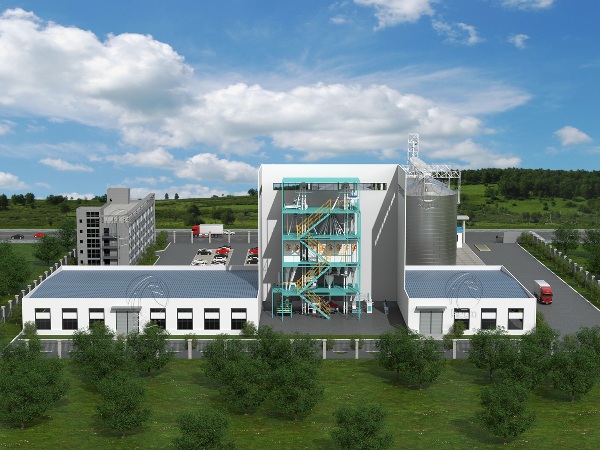

We offer a range of solutions tailored to your needs, including small feed granulators for smaller farms and larger feed pellet plants for extensive processing operations. Today, we will focus on our feed pellet plants, designed for various production capacities including 1-2 tons/hour, 3-4 tons/hour, 5 tons/hour, 8-12 tons/hour, and 12-15 tons/hour.

Importance of Quality Feed Ingredients

When producing feed, the quality of ingredients is paramount. Here are key factors to consider:

Moisture Content: The moisture content of raw feed materials should ideally be below 13% to 14%. Excessive moisture can lead to high water content in the compound feed, increasing the risk of germination and cholera, which can compromise storage conditions.

Mold-Free Raw Materials: Any raw material that shows signs of mold should be discarded, as it is unsuitable for production.

Nutritional Content: The nutrient profile must meet the specific needs of the animals. Different feeds have varying crude fiber content, with materials like forage grass and straw unsuitable for monogastric animals such as pigs and chickens.

Components of Our Poultry Feed Granulator Plant

Our poultry feed granulator plant includes the essential equipment for a complete production line:

Hammer Mill Crusher: This machine effectively crushes raw materials into powder, facilitating mixing.

Feed Mixer Machine: The feed mixer can be customized for the homogeneous blending of various ingredients. For instance, when producing chicken feed, you can add oil directly into the mixer. For cattle feeds, you might consider adding honey or sugarcane water. Our honey adder machine can seamlessly incorporate honey into your mix.

Feed Granulator Machine: This is the heart of the processing line. It allows for the production of different animal feeds based on specific requirements. To achieve different feed formulations, you can swap out ring dies and rollers as needed. The required compression ratios vary by feed type:

Chicken feed: 1:7-11

Pig feed: 1:5-7

Fish feed: 1:13-16

Shrimp feed: 1:25-31

Steam Boiler: Integrating a steam boiler can enhance the process. The steam produced helps to mature the raw materials, ensuring optimal powder quality. The recommended steam addition is 4%-6% of the total granulation output. Adjustments to steam pressure can be made based on seasonal temperature variations.

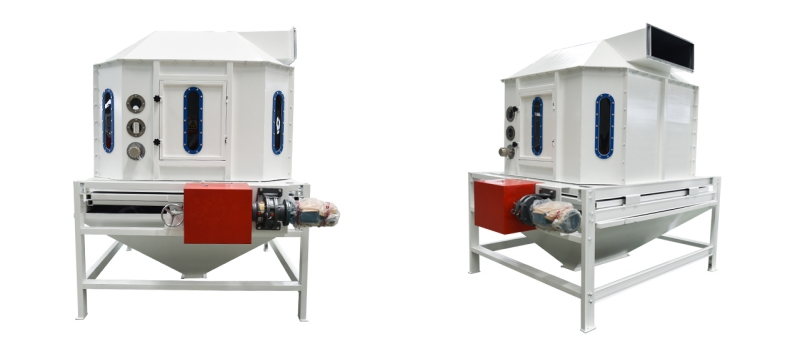

Feed Cooler Machine: Utilizing counter-flow cooling, this machine ensures that the pellets are uniformly cooled. After cooling, the temperature of the finished product should not exceed 3℃-5℃ above the ambient room temperature.

Rotary Classifier Machine: This screening device employs horizontal rotary motion to separate particles effectively. Each layer includes an anti-blocking cleaning mechanism to prevent clogging, extending the operational life of the equipment.

Crumble Machine: Essential for creating smaller pellets, this machine is crucial for ensuring that smaller chicks can consume the feed comfortably.

Packing Machine: Our automated packing solutions can package pellets in sizes of 5kg, 25kg, 50kg, and more. Different machines are required for powder and pellet feeds, so it’s important to specify your needs in advance.

Oil Sprayer: If you are raising broiler chickens, an oil sprayer can enhance feed palatability. Since broilers typically grow within 40-45 days, ensuring that pellets are adequately coated with oil is beneficial for optimal growth.

Installation Support

We understand that installation can be a significant concern, especially across international borders. To facilitate this, we offer:

Installation Drafts: We can provide detailed installation plans to assess ease of setup.

Local Installers: If you prefer assistance, we have local installation professionals who can guide you through the process.

On-Site Support: For larger capacities (e.g., 10 tons/hour), we can dispatch our engineers to your location to assist with machine debugging and to train your staff on operational procedures.

For example, we recently assisted customers in Kenya and Ethiopia with their installation, showcasing our commitment to customer support.

Conclusion

At Herm Machinery, we are dedicated to providing comprehensive solutions for your feed processing needs. Our range of equipment, expertise in production, and commitment to customer service position us as your ideal partner in the feed industry. We look forward to the opportunity to collaborate with you!

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Phone/Whatsapp: 0086-18037508651