Daily Maintenance Tips for Feed Crusher Machines

The Role and Maintenance of the Feed Hammer Mill in Animal Feed Processing Plants

The feed hammer mill is a critical piece of equipment in animal feed processing plants. Its primary function is to pulverize raw materials, increase particles' surface area, and improve feed nutrient solubility in animal digestive juices. This process boosts the overall efficiency of nutrient absorption in livestock. As such, maintenance and operation personnel need to be equipped with the knowledge to diagnose and resolve common issues quickly to ensure minimal production downtime.

Make a Quick Inquiry Now !I. Common Causes and Solutions for Feed Hammer Mill Vibration

Vibration is a prevalent issue in feed hammer mills, often caused by improper assembly, wear and tear, or other imbalances. Below are common causes and their solutions:

Misalignment of Motor and Pulverizing Device

The feed hammer mill typically connects directly to the motor for easier maintenance. However, improper alignment during assembly can cause significant vibration. Ensuring the motor and mill are precisely aligned when assembling the unit is crucial.

Non-Concentric Rotors

If the rotors of the motor and hammer mill are not concentric, it can cause vibration. Adjusting the motor’s position left or right can help achieve concentricity between the two rotors.

Uneven Rotor Bearings

An imbalance can occur if the bearing surfaces are not aligned on the same plane, leading to non-concentric rotor movements. Operators should verify that both shaft ends are aligned to maintain a balanced operation.

Vibration in Specific Parts of the Crushing Chamber

This issue can arise from improper coupling between the rotor and the motor, or due to imbalanced hammer weights. Uneven hammer quality can disrupt the balance, leading to increased vibration. Re-select and install hammers symmetrically to ensure weight discrepancies are kept below 5g.

Broken Hammers or Debris in the Chamber

Hard debris or broken hammers inside the crushing chamber can disrupt the balance of the rotating rotor, causing excessive vibration. It’s important to immediately stop the machine, inspect the chamber, and address any issues before resuming operations.

II. Addressing Bearing Overheating

Bearings are essential components of a hammer mill feed grinder. Their condition directly impacts the mill’s efficiency and longevity. Here’s how to manage and prevent bearing overheating:

Misalignment and Uneven Bearing Seats

Uneven bearing seats or non-concentric rotors can create additional load on the bearings, leading to overheating. If this occurs, shut down the machine immediately to correct alignment and prevent premature bearing damage.

Inappropriate Lubrication

Proper lubrication is crucial for bearing longevity. Lubrication should fill 60-70% of the bearing space—too much or too little can hinder the bearing’s ability to reduce friction and dissipate heat. Regularly check and replace lubricants to maintain optimal lubrication.

Improper Fitment of Bearings

Overly tight or loose fits between the bearing, bearing cover, and shaft can cause overheating. Symptoms include friction noise and noticeable movement during operation. If these issues occur, stop the machine, trim the friction areas, and reinstall the bearings correctly.

III. Resolving Screen Blockage in Hammer Mill Feed Grinders

Screen blockage is another common issue in hammer mill feed grinders, affecting the efficiency of grinding and feed flow. While improper sieve design may contribute, operational issues are often the main culprits:

Excessive Feeding Speed

Overfeeding increases the load on the grinder, leading to screen blockage. Monitor the ammeter to ensure that the feed rate does not exceed the motor’s rated current. Generally, the hammer mill’s operating current should be around 85% of its rated current. If the current spikes, adjust the feed rate to prevent motor overload.

Worn or Broken Hammers, High Moisture Content

Worn hammers, broken screens, or high moisture content in raw materials can cause blockages. Regularly inspect and replace damaged hammers, keep screens clean and in good condition, and ensure the moisture content of raw materials is below 14% for optimal grinding.

IV. Daily Maintenance Tips for Feed Hammer Mills

Routine maintenance is key to ensuring long-term, trouble-free operation of feed hammer mills. Here are essential maintenance practices:

Adjusting Belt Tension

New machines tend to have transmission belts that stretch with use. Regularly check belt tension and adjust as needed to ensure the belt’s longevity and maintain transmission efficiency.

Inspection of Wear Parts

Frequently inspect worn parts, including hammers, screens, and bearings, to maintain consistent product quality and production output. Replace parts showing significant wear to avoid unplanned downtime.

Blade and Bushing Wear Check

Worn blades and bushings can lead to reduced productivity and coarser grinding. Regularly inspect these components and replace them when wear is evident to maintain the mill’s efficiency.

Conclusion

Effective maintenance and quick troubleshooting of feed hammer mills are crucial for maintaining production efficiency and quality in animal feed processing plants. By ensuring proper alignment, maintaining lubrication, monitoring feed rates, and performing regular maintenance, operators can minimize downtime and extend the life of the equipment. A well-maintained hammer mill ensures that animals receive nutritionally balanced and efficiently processed feed, contributing to better growth and productivity.

This refined version is more structured and detailed, providing better guidance for maintenance and troubleshooting of feed hammer mills, while also emphasizing the importance of proper operation for maximizing productivity.

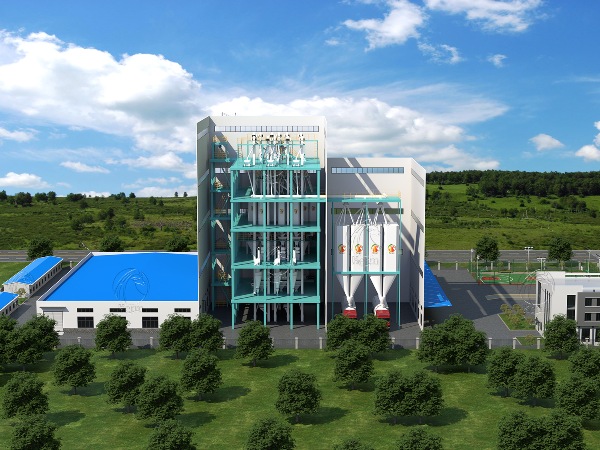

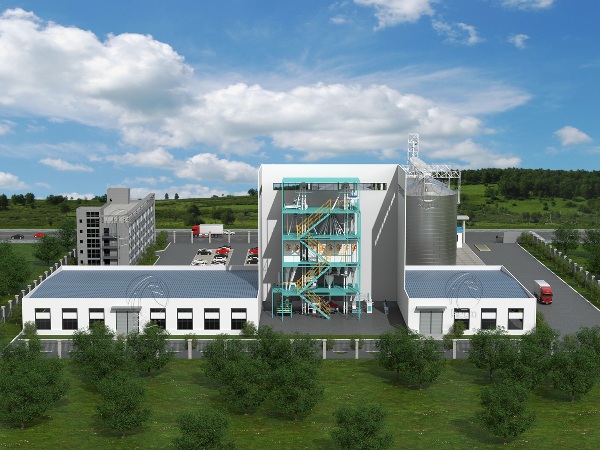

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Phone/Whatsapp: 0086-18037508651