How to Use a Feed Pelletizer?

If you're considering starting a farm or venturing into the feed processing business, our feed pellet machine can be a key asset to help you meet market demand. Currently, animal feed comes in two primary forms: powder feed and pellet feed. Let's delve into each, highlighting their production processes and advantages, so you can decide which suits your needs.

Powder Feed Production:

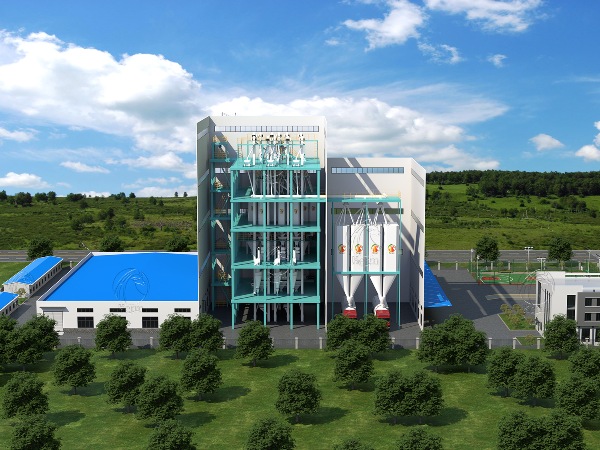

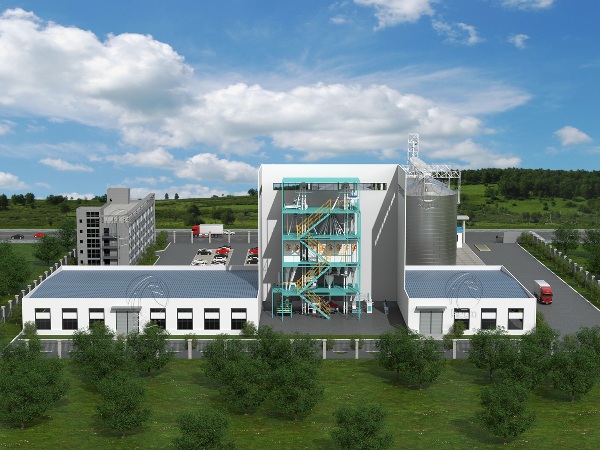

Powder feed is produced using a hammer mill crusher, which grinds raw materials into fine powder. Next, a feed mixer blends different types of materials evenly. If you intend to distribute the feed in bags, you can incorporate a packaging machine into your setup. Alternatively, a tractor can be used for larger-scale transport. Below is an example of a customer’s 10T/H feed powder line, featuring efficient machines with high productivity. If bagging is necessary, a packaging machine can be added for convenience.

Focus on Feed Pellets:

Today, we will focus on feed pellets, which offer several advantages over powder feed, particularly in terms of storage, transportation, and nutritional consistency. We offer two types of feed pellet mills: flat die and ring die feed pellet mills. Each type has its benefits, depending on your scale of operation.

Flat Die Feed Pellet Mill:

The flat die feed pellet mill, as shown below, is ideal for small to medium-sized farms. With a capacity ranging from 100kg to 1000kg, it is straightforward in design and easy to use. If you’re aiming for better efficiency, this machine can be paired with additional equipment such as a crusher machine or a mixer machine. This combination not only enhances productivity but also reduces labor costs. For locations where electricity supply is limited, we offer a diesel-powered version.

Ring Die Feed Pellet Mill:

For larger production capacities, the ring die feed pellet mill is the optimal choice. This model operates with a boiler, which produces steam that helps ripen the feed material, improving its nutritional profile. The machine comprises three parts: a stainless steel conditioner, a feeder, and the pellet machine itself.

The stainless steel conditioner is equipped with steam injection points that treat the feed material with steam. The incoming steam temperature is 105°C, while the outgoing temperature is 75°C. The optimal steam addition is 4%-6% of the output—too much or too little steam can negatively impact pellet quality.

You may be wondering, what exactly is a conditioner? The conditioner ensures the feed material undergoes hydrothermal treatment, which softens it, makes starch gelatinize, and denatures protein. This results in improved pellet quality, better digestibility, and enhanced palatability.

Advantages of Pellet Feed Machines:

Improved Feed Pellet Quality: The conditioning process raises the moisture and temperature levels of powdered feed, making granulation easier and producing higher-quality pellets.

Better Digestibility: Hydrothermal treatment promotes starch gelatinization and protein denaturation, making feed more digestible for animals.

Reduced Feed Waste: Pellet feed reduces animal picky eating and wastage by ensuring a consistent particle size and complete nutritional profile.

Higher Feed Conversion Rate: Feeding pellet feed to poultry and pigs can improve the feed conversion rate by 10%-12% compared to meal feed. For fattening pigs, it can increase daily weight gain by 4%, while reducing the feed-to-meat ratio by 6%.

Pellet Feed vs. Powder Feed: Which to Choose?

Cost: Powder feed is cheaper to produce and requires less labor, making it a cost-effective option.

Transportation: Powder feed has a lower bulk density, making it less efficient for transport. Pellet feed, by contrast, increases bulk density by 40%-100%, making it easier to store and transport.

Storage and Handling: Pellet feed does not generate dust, reducing environmental pollution and protecting the respiratory health of animals. It also avoids segregation of materials, which is common in powdered feed.

Feed Waste: Pellets minimize waste due to animals’ selective feeding habits and prevent dust-related losses during feeding.

Lastly, pellet feed can be customized in various sizes according to your animals' needs, and its high-temperature processing effectively kills harmful pathogens like Salmonella, ensuring safer feed for both animals and humans.

Whether you choose powder feed or pellet feed depends on your specific requirements and the type of animals you're raising. If you'd like more information or need help selecting the right equipment, feel free to contact us for personalized advice.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Phone/Whatsapp: 0086-18037508651