Turnkey 5T/H Feed Powder Production Line to Uzbekistan

Henan HERM Machinery Provides 5T/H Powder Feed Production Line for Bukhara Customers in Uzbekistan, Boosting Poultry Farm Production Efficiency

Henan HERM Machinery recently supplied a complete 5T/H powder feed production line to a customer in Bukhara, Uzbekistan, for their poultry farm feed production. This project not only demonstrates Henan HERM Machinery's leading technology in the feed processing equipment field but also highlights the company's strong capability to provide customized, one-stop services. Through this project, the customer significantly improved their production efficiency and overall operational cost.

Make a Quick Inquiry Now !Customer Background and Requirements:

The customer operates a poultry farm located in Bukhara, Uzbekistan, and primarily produces chicken feed powder for their use. The customer urgently needed a high-performance, stable production line to increase production efficiency and ensure feed quality. The equipment was required to meet a specific production capacity while adapting to the existing factory layout. The customer specifically emphasized the need for energy efficiency, ease of operation, and convenient maintenance to ensure high-efficiency production, reduce operating costs, and maintain long-term stable production.

Henan HERM Machinery Solution:

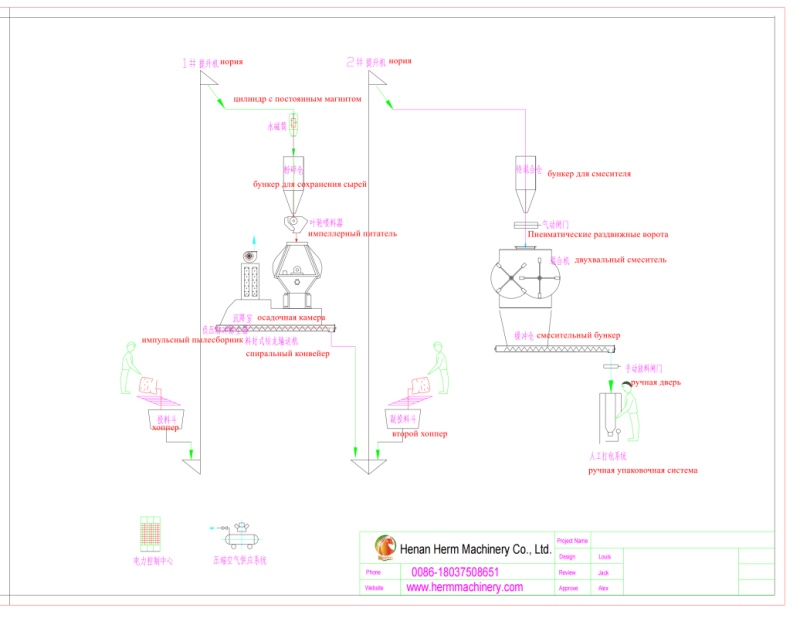

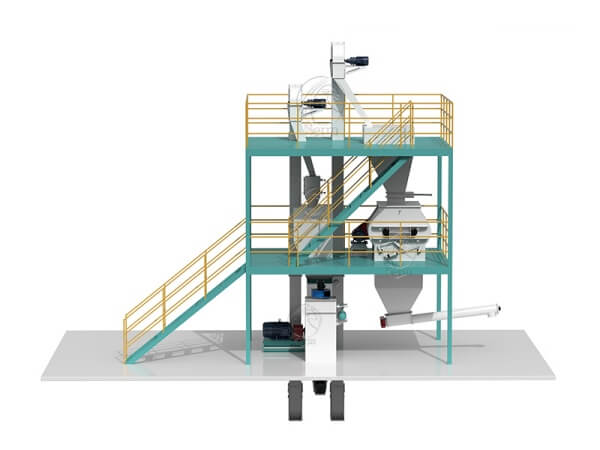

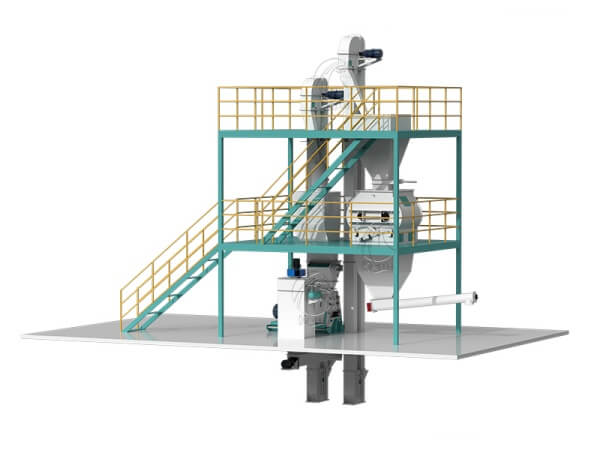

Henan HERM Machinery’s team customized a 5T/H powder feed production line to meet the customer's capacity requirements while optimizing space layout and operational processes to enhance overall production efficiency. Our solution focused on energy savings, convenience, and safety while ensuring the equipment's long-term stable operation, all tailored to the customer's factory height and space limitations.

Key Equipment Configuration:

45kw Water-drop Hammer Mill: Featuring a high-efficiency water-drop design with a Siemens motor, infinitely variable speed feeder, and permanent magnet drum, this mill effectively improves crushing efficiency and ensures uniform feed texture while reducing power consumption for high-efficiency, low-energy production.

Pulse Dust Collector: The high-efficiency pulse dust collector ensures a clean working environment by removing dust generated during production, preventing any adverse effects on worker health and equipment operation.

Double-shaft Paddle Mixer: This high-efficiency mixer completes a 0.5-ton batch in 90 seconds, ensuring the evenness and stability of the feed formula and improving feed utilization.

Oil Additive System: The precise oil additive system ensures uniform and accurate oil addition to the feed, further enhancing feed quality.

Bucket Elevator: The bucket elevator is used to transport powder and finished products, ensuring smooth connectivity between production stages and continuous production flow.

Design Highlights and Optimizations:

In addition to meeting the customer’s production needs, Henan HERM Machinery made several design optimizations:

Simplified Operational Flow: The original design included a screw conveyor, but this was removed and replaced with a more efficient bucket elevator. The height of the bucket elevator was also optimized to streamline operations and improve overall work efficiency.

Addition of Temporary Storage Bins: To ensure continuous production and avoid downtime due to untimely material supply, two 2-cubic-meter temporary storage bins were added above the hammer mill and mixer. This design minimizes energy waste and ensures a smoother production process.

Safety and Easy Maintenance Design: Despite the total height of the production line being only 8 meters, Henan HERM Machinery added safety features such as stairs and guardrails to ensure worker safety. These features also make future maintenance and repairs more convenient.

Henan HERM Machinery’s One-stop Service Advantage:

Henan HERM Machinery adheres to a customer-first philosophy and is committed to providing comprehensive, professional one-stop services that support customers from project initiation to line commissioning, operation, and maintenance.

Demand Analysis and Custom Solution Design:

At the start of the project, our technical team worked closely with the customer to analyze their production requirements, factory space, and future development plans. Based on this information, we designed the most suitable equipment configuration and production line solution. Whether it's equipment selection, production process design, or factory layout, Henan HERM Machinery always provides the most optimized plan to ensure the best fulfillment of the customer's needs.

Comprehensive Design and Technical Support:

Henan HERM Machinery provided the customer with detailed 3D design drawings, helping them understand the layout and operational flow of each component. These drawings not only guided the installation process but also ensured the smooth operation of the production line. Our design team collaborated closely with the customer to provide a full factory layout and rendering, maximizing space utilization and suggesting improvements based on the actual factory situation.

Project Management and Seamless Installation and Commissioning:

From equipment transportation to installation and commissioning, Henan HERM Machinery provides full project management services. We ensure the project is completed on time and with high quality, arranging for a specialized technical team to assist with installation and commissioning to ensure the production line starts smoothly. Additionally, we provide detailed training to the customer’s operators, ensuring they can operate and maintain the equipment proficiently, maximizing production efficiency.

After-Sales Service and Technical Support:

After installation, our after-sales team continues to offer long-term technical support and equipment maintenance services. Whether it’s troubleshooting, production line optimization, or equipment upgrades, Henan HERM Machinery maintains close contact with the customer to ensure the production line runs smoothly for the long term. We also provide spare parts to ensure any issues during operation can be resolved quickly and efficiently.

Customer Feedback:

The customer expressed high satisfaction with Henan HERM Machinery’s solution, particularly appreciating our comprehensive support in equipment selection, production line design, and after-sales service. They reported that the poultry farm's feed production line was successfully put into operation, significantly improving production efficiency and ensuring better feed quality. Additionally, the energy-efficient and low-energy-consuming equipment helped the customer reduce production costs. The customer highly praised Henan HERM Machinery’s professional capabilities and one-stop service, with plans to continue cooperating on future projects.

Henan HERM Machinery’s Strengths:

This collaboration further confirms Henan HERM Machinery’s leadership in the feed processing system field. With years of professional experience, we offer customized one-stop services that cover everything from equipment design and factory layout to installation and after-sales support. Moving forward, we will continue to innovate and provide efficient, stable, and energy-saving solutions to help customers remain competitive in the global market.

Contact Us:

If you are looking for an efficient, stable feed production line or wish to improve your existing production line's efficiency, Henan HERM Machinery is your ideal choice. We provide tailor-made solutions to ensure you get the best return on your investment. Contact our sales and technical teams for more project inquiries and solutions. Henan HERM Machinery’s “One-stop Service” ensures more efficient, stable production and supports the successful development of your business!

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Whatsapp: 0086 18037508651