How to Start a Feed Production Plant in Ethiopia

Ethiopia's agricultural scene is booming, especially in terms of livestock products. This growing demand presents a fantastic opportunity for anyone looking to set up a feed production plant. With a vibrant livestock sector supporting millions, a well-run feed plant can boost the economy and provide essential animal nutrition. Let’s break down the key steps to get your feed production plant off the ground in Ethiopia, from market research to everyday operations.

Market Research

Industry Analysis

First, you need to get a handle on the feed market. There’s been a noticeable uptick in demand for high-quality feed, driven by more livestock and changing diets. Conducting a SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) will help you understand the competitive landscape. Here are some questions to consider:

What types of feed are hot right now?

Who are the main players in the market, and what portion do they control?

How are prices fluctuating?

Target Customers

Next, identify your target customers. They might include:

Smallholder farmers, who typically look for affordable and basic feed.

Large-scale farms might want specialized or high-nutrition feed. Surveys or interviews can provide insights into what these customers need and prefer.

Business Plan

Vision and Goals

Having clear long-term and short-term goals is essential. Think about objectives like:

Gaining a certain market share within the first three years.

Offering a variety of products tailored to different types of livestock.

Financial Planning

A solid budget for your initial investment is crucial. This should cover:

Equipment costs (machines, tools).

Facility construction costs.

Ongoing operating expenses (labor, utilities, raw materials). A break-even analysis can help you figure out how long it will take to start turning a profit.

Legal and Registration Requirements

Business Registration

Getting your business registered in Ethiopia involves a few steps. You’ll need to gather documents like:

Articles of incorporation.

A tax identification number.

Necessary business licenses. Make sure you understand the local laws to stay compliant.

Licenses and Regulations

It's vital to understand the rules governing feed production, including:

Environmental regulations regarding waste.

Health and safety standards.

Quality assurance requirements from local authorities. Research the specific permits you’ll need to manufacture and sell animal feed.

Site Selection and Facility Construction

Location

Picking the right location is critical. Consider factors such as:

How close you are to raw material suppliers to save on transport costs.

Access to major transport routes for easy distribution.

Availability of utilities like water and electricity, as well as skilled labor.

Facility Design

Designing your facility involves planning for efficient production flow. Think about:

I am setting up areas for raw material storage, processing, and finished product storage.

Compliance with safety regulations, including fire exits and worker safety.

Equipment Procurement

Production Equipment Selection

Choosing the right equipment is key to smooth operations. Essential machines include:

Grinders for raw materials.

Mixers for blending ingredients.

Pellet mills for making feed pellets. Stay updated on the latest technology that can improve efficiency and product quality.

Supplier Evaluation

Finding reliable equipment suppliers is important. Evaluate potential suppliers based on:

Their reputation and reliability.

After-sales support and maintenance services.

Warranty terms.

Raw Material Supply Chain Management

Raw Material Procurement

Identifying sources for key ingredients like maize and soybean is essential. Build relationships with:

Local farmers for a consistent supply of grains.

Suppliers of specialized ingredients to boost nutritional content.

Supply Chain Optimization

Developing a logistics plan for transportation and storage is vital for keeping costs down and maintaining product quality. Consider:

Just-in-time inventory systems to minimize storage costs.

Local transportation options for timely deliveries.

Production Process and Quality Control

Production Workflow

Clearly outlining your production process helps maintain consistency. The typical workflow includes:

Receiving raw materials.

Grinding and mixing.

Pelleting and cooling.

Packaging and storage.

Quality Management

Implementing a robust quality control system ensures your products meet safety and nutritional standards. Key practices include:

Regularly inspecting raw materials and finished products.

Adopting quality management systems (QMS) like ISO 9001.

Human Resource Management

Recruitment and Training

Hiring skilled staff is essential for smooth operations. Focus on:

Attracting local talent with experience in agriculture or manufacturing.

Offering comprehensive training programs on equipment operation and safety protocols.

Marketing and Sales Strategies

Marketing Strategy

Creating a solid marketing plan that includes both online and offline strategies will help you reach your audience effectively. Some ideas include:

Building an easy-to-navigate website that showcases your products.

Using social media for outreach and engagement.

Sales Network

Establishing distribution channels and partnerships with local businesses can help you reach more customers. Consider:

Collaborating with agricultural cooperatives to reach smallholder farmers.

Setting up a direct sales team to engage large farms and enterprises.

Sustainable Development and Future Outlook

Sustainable Production

Adopting environmentally friendly practices in your production process will not only appeal to consumers but also help reduce environmental impact. Look into:

Using by-products from local agriculture as feed ingredients.

Implementing energy-efficient technologies.

Market Expansion

Identifying future opportunities, like exports or new product lines, will ensure you can adapt and grow. Research international markets and assess local demand for specialty feeds.

Conclusion

Starting a feed production plant in Ethiopia involves navigating several strategic steps, from thorough market research to embracing sustainable practices. While challenges may arise, the potential for growth and contributions to the agricultural sector are significant. By focusing on quality, efficiency, and innovation, you can build a successful feed production business that meets the needs of Ethiopian livestock farmers and supports economic development.

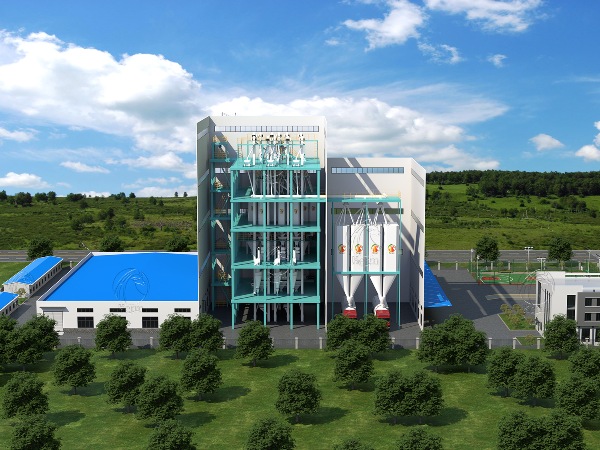

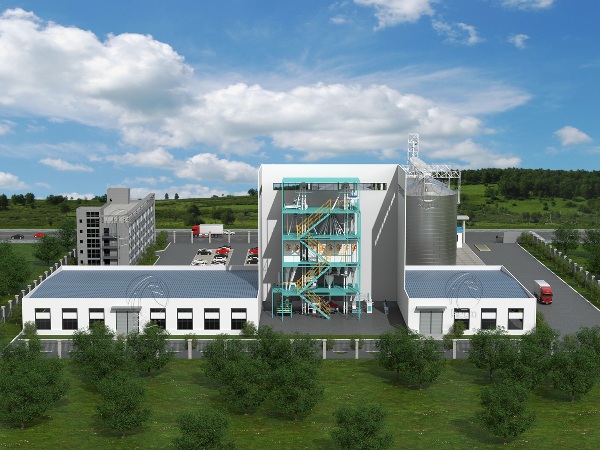

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Phone/Whatsapp: 0086-18037508651