MZLH350 Wood Biomass Pellet Mill Introduction

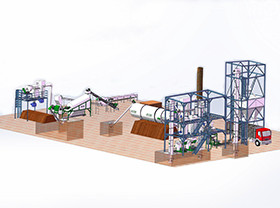

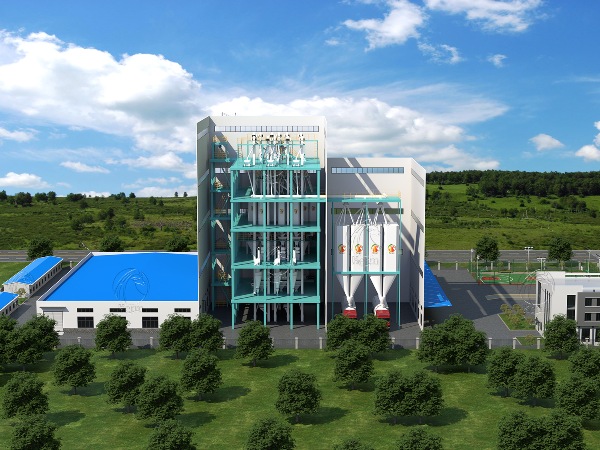

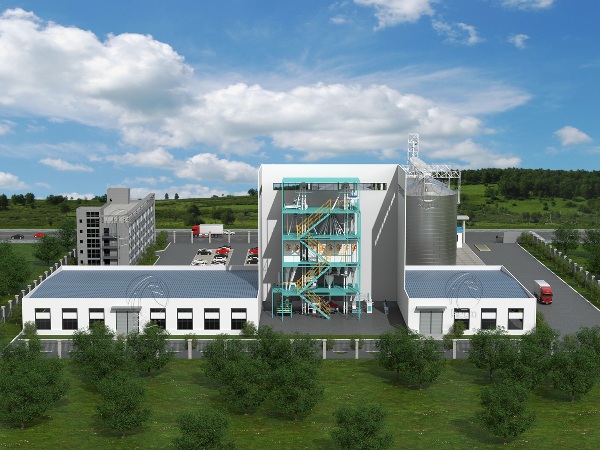

Herm machinery high-performance 3-3.5 tons/hour biomass wood pellet production line is specially designed for all manufacturers based on the principle of biomass recycling, such as biomass fuel manufacturers, wood board factories, organic fertilizer factories, feed factories, carton factories, etc. The main technological process of 3-3.5t/h biomass wood pellet production line: raw material crushing, drying, granulating, cooling, screening, and packaging. The main equipment of a complete 3-3.5 t/h biomass wood pellet machine equipment includes a wood chipper, wood hammer pulverizer, drum rotary dryer, wood pellet machine, countercurrent cooler, vibrating screen classifier, automatic bagging system, electric control cabinet, etc.

Make a Quick Inquiry Now !

Raw Materials Of Biomass Wood Pellet Production Line

3-3.5t/h biomass wood pellet production line is mainly suitable for the production of wood, sawdust, straw, rice husk, organic fertilizer, chicken manure, cow manure, pig manure, horse manure, wood chips, shavings, logs, branches, peanut shells, Palm trees, oil palm leaves, palm fibers, palm kernel shells, waste paper, hay, alfalfa, bagasse, forestry residues, hops, straw, hemp, etc.

How To Make Biomass Wood Pellet?

Wood biomass is a common feedstock for pellet production and includes wood, logs, wood chips, wood shavings, or sawdust from pine, acacia, cypress, beech, oak, etc. Generally speaking, if your raw material is softwood, you can pellet it without additives; if your raw material is hardwood, you need to add a certain amount of softwood or binder (hardwood is more difficult to pellet).

The wood biomass pellets production technology goes this way:

1. Crushing of raw materials: usually sawdust, logs, or wood must be broken before pelletizing. The reason is that these wood raw materials are all bulky and cannot be pelletized directly. This process requires a wood chipper and a hammer mill.

2. Screening of broken materials: Sometimes there are impurities such as stones or metal chips in the raw materials. These impurities can damage the granulator. So they have to sift.

3. Drying: Sawdust usually contains moisture. In this case, a dryer is essential. For capacities below 1 ton/hour, an airflow dryer is sufficient. But for larger volumes, a tumble dryer is a great help.

4. Woody biomass pellet production: Wood pellet machines also have different capacities. 50-500kg/h, use a flat die granulator; >500kg/h, use a ring die granulator or multiple flat die granulators.

5. Particle cooling and screening: The temperature of the pellets produced by the pellet mill is high; therefore, a cooler is needed to cool the pellets. In addition, the counter-flow cooler can also screen broken granules or raw material powder to obtain good-quality granules.

6. Pellet packaging: Pack woody biomass pellets in bags for easy storage, transportation, and sales. They can be packed in pouches and large bags.

The above is the process of the entire wood pellet production line, and other biomass raw materials go through similar steps.

Make a Quick Inquiry Now !

Biomass Pellets Application

1. Industrial boilers: Bioparticles can partially (or fully) replace coal or fossil fuels for co-fired heating in large-scale industrial operations to reduce energy costs.

2. Power plants: Biomass particles can be used in power plants to solve the problem of insufficient power supply.

3. Animal bedding: Bio-particles made of coniferous wood are high-grade animal bedding for the animal feeding experience.

4. Building heating: Biomass pellets can be used in pellet stoves or stoves in schools, hospitals, shopping malls, companies, etc. to heat rooms, and biomass pellets can also be used for cooking.